WHAT CAN WE DO FOR YOU?

PIRANHA Manufacturing can take your projects from start to finish

Piranha Electronic Manufacturing is a complete electronics manufacturing services (EMS) and solutions provider to original equipment manufactures and product design and development firms of computer related products supporting a diverse range of business enterprise applications such as, wireless infrastructure, Internet of things (IOT) life science, aerospace and defense, professional consumer (Prosumer), wearables, industrial controls, electric Vehicle (EV), casino gamming, embedded computing, and smart grid. The company manufactures printed circuit board assemblies (PCBA), provides engineering support for prototypes, quick turn assembly and has box assembly capabilities to volume manufacturing, both domestically (California USA) and abroad (Danang Vietnam). We are a boutique service provider targeting low and medium mix and high volume, from low to complex project deliverables.

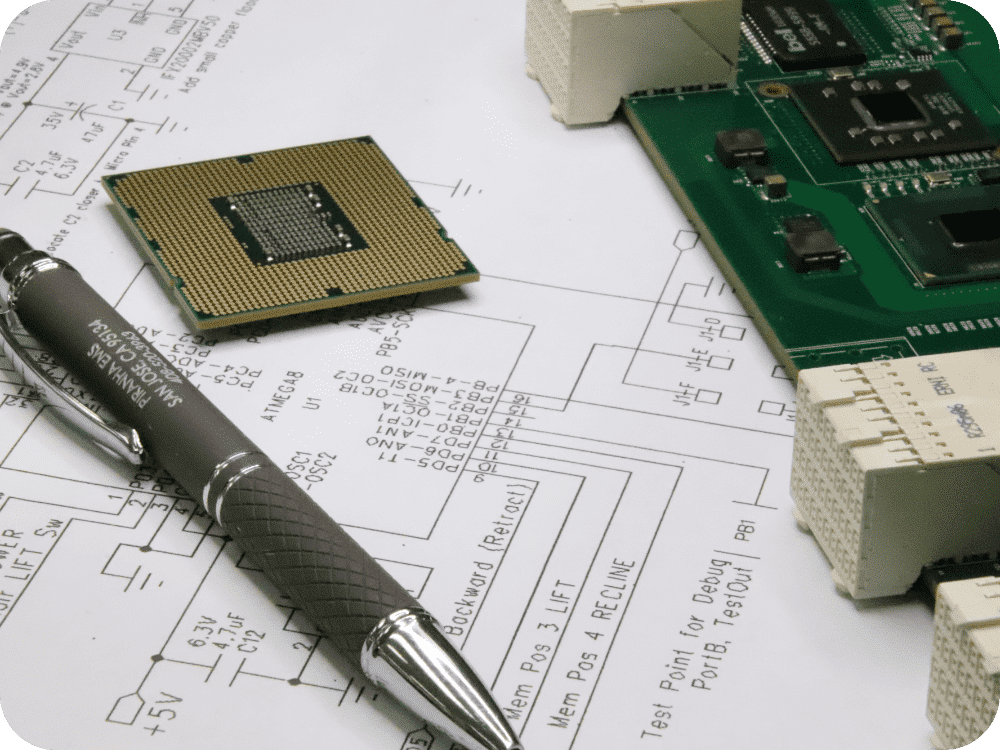

There are many aspects to consider when designing and routing a PCB. Parts, parts placement, size, form factor, and as importantly design for manufacturing. Many overlook these basic principles that could very well break the bank and in turn, price you out of the market. And in some cases, well before you even launch. We aim to align world class talent to your novel idea then collide them into producible repeatable world class products.

The PCB layout and design is a specialist skill requiring knowledge of not only of the PCB design software and PCB CAD system, but also a variety of standards and techniques used to ensure that the basic circuit design is successfully transferred to an overall printed circuit board that can be manufactured in an electronics circuit manufacturing environment.

In order the printed circuit board can be designed satisfactorily, it often helps to have some guidelines that can be followed, although there is no substitute for experience.

At Piranha, we know the ultimate conclusion of a project is rooted in its inception. Since 2013, Piranha has been helping Bay Area startups and fortune 2000 companies alike to establish positive beginnings to their project’s life cycles.

Our complete suit of services leverage relationships to facilitate fast turnaround on projects and are designed to help streamline even the most ambitious technology.

During the initial planning stages, we work closely with the designer and provide advice on the manufacturing techniques, keep outs, and material availability. We assemble a project team that is headed up by an operation manager whose experience comprises of materials buying and planning, manufacturing processes, and is your primary handler.

This team member is key to the expediency of the project deliverables. All our employees are cross-trained in multiple disciplines which enables the project to move with a great deal of speed, integrity, and care.

Vietnam is a fast-rising star in global manufacturing. It scored the second annual flow of foreign direct investment (FDI) in 2019 and gained more attention as an alternative hub when Covid-19 disrupted Manufacturing worldwide. Piranha has embarked on a key strategic journey into Da Nang Vietnam leveraging some of the finest talents and a World-class factory built from the ground up aimed to deliver an experience that is truly unique.

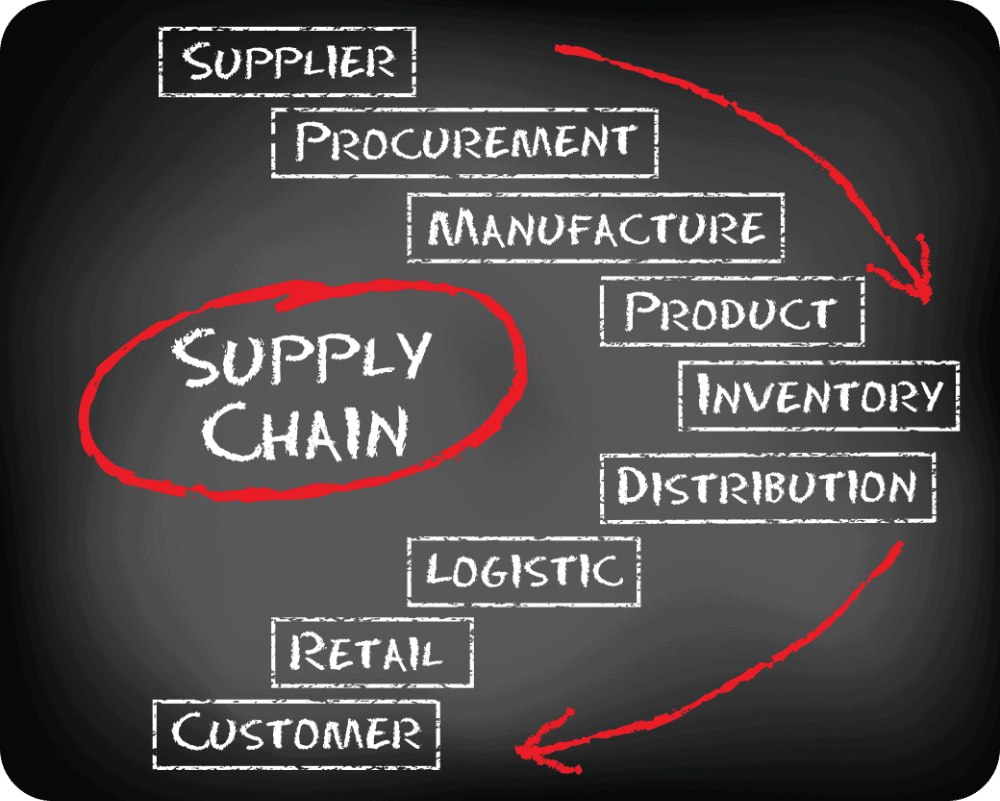

The integrated supply chain is a process wherein every phase from procurement of raw material to production, quality control, integration to shipments eventual delivery is streamlined and inseparable.

It eventually boils down to how a company manages to extract the benefits and overcome the challenges or avert complications.

Should supply chain integration be effective and efficient, a company can reap long-term multifaceted rewards. Piranha has a strong alliance of partners proven over years of accomplishment to deliver those rewards.